Promotional Features

How frozen dough technology is raising efficiency and quality

Frozen doughs are used across a range of baked goods from breads to pastries as a convenient and efficient way to prepare and store items through the supply chain from manufacturer to retailer.

The longer shelf life of frozen dough offers a number of advantages, such as the convenience of production on demand and the ability to reduce equipment and labour costs. New technologies and innovations to preserve the shelf life of frozen doughs have also accelerated the market, leading to wider product availability and higher quality goods.

Frozen dough technology can be employed for sweetened doughs, European-style doughs and doughs for pastry products, among others. Today, frozen dough is a growing market thanks to the rising popularity of baked goods in developing countries around the world; in 2022 the global frozen dough market was worth US $18.59 billion, with emerging economies, particularly developing counties in the Asia Pacific region, expected to drive market growth.1

Improving frozen dough

The key ingredients in dough are cereal-based flour, water, salt, fat and sugars. Leavening agents, such as yeast, and improvers – stabilisers and supplementary enzymes – are also added.2 The shelf-life of fresh yeast is 45 days when chilled but during this period it will gradually lose its activity by 20%. However, when fresh yeast is added to dough and blast-frozen to prevent fermentation, the loss of yeast activity is slowed down; upon thawing, it is restored to an active state.

As baked goods are susceptible to damage and spoilage during transport and storage, freezing is widely used as a preservation method but the process can impact the final quality. In general, frozen dough can be divided into two groups. Firstly, those which require freezing only for shorter periods of around one month. These can have a lower yeast content and are better able to maintain their original flavour.

Meanwhile doughs which are frozen for longer periods of three-to-six months during transportation and storage require a higher yeast content and a stronger flour mix, with a protein content of over 13%. This helps to prevent the flour from becoming damaged by ice crystals during the freezing process. These doughs benefit from the addition of improvers to help strengthen gluten and improve consistency.

For manufacturers, improving and maintaining the quality of products made with frozen doughs can be a challenge and, despite advances in technology, products made from frozen doughs may experience issues, such as a prolonged final leavening time, reduced loaf volume and poor texture.

The quality of bread and other baked goods made from frozen dough is influenced by dough formulation, as well as process parameters such as dough mixing time, freezing rate, storage duration and thawing rate. Breads made from frozen dough can suffer from loss of dough strength, a decrease in yeast activity and the retention capacity of CO2 and require longer fermentation time. This, in turn, can cause damage to the gluten network and lead to poor baking performance, including deterioration in the texture and volume of the final product.2

The crystallization of water during freezing may cause physical damage to the gluten network or the leakage of the yeast cell membranes. Ice crystals which occur during the freezing process are crucial factors affecting dough quality. These impact the activity of the yeast and gas production, leading to loss of gluten structure and a lower quality dough. Furthermore, during freezing and frozen storage, yeasts may release reducing compounds, such as glutathione, which can weaken the gluten network and result in the loss of gas retention.3

How can manufacturers help to protect yeast and gluten in dough from potential damage, improve freezing tolerance and maintain the volume and sensorial characteristics of the dough, thereby improving the finished product?

Advances in frozen dough technology

Freeze-resistant yeast and specialized dough improvers are essential raw materials for frozen dough technology. Freeze-resistant yeast can maintain stable fermentation activity for extended periods at temperatures at -18°C. Specialised dough improvers protect the yeast cells and gluten in the dough from potential damage, thereby resulting in stable and high-quality pre-baked goods. These can be used in a range of options, including unfermented frozen dough, pre-fermented frozen dough, semi-baked and fully-baked frozen dough, depending on processing types and manufacturing requirements.

Angel Yeast’s cold-resistant Semi-Dry Yeast is a strain of baker’s yeast (Saccharomyces cerevisiae) and is specially designed to ensure optimum stability of yeast activity in frozen dough. Available as free-flowing granules for easy and accurate dosing, it helps to maintain a consistent level of fermentation activity even after prolonged storage and can be used to enhance the shelf life of frozen dough from 15 days to six months, depending on requirements, by adjusting the amount of yeast accordingly. The recommended dosage for Angel Semi-Dry Yeast is between 1.5% and 3%, approximately 50% of the amount of compressed yeast, while achieving longer shelf life and enhanced flavour in the finished product.

Angel Yeast also manufacturers F-99 Frozen Dough Improver for use in frozen doughs for sweet dough, flaky dough and other types of frozen dough. When mixed into the flour and other ingredients at a dosage of between 0.5% and 2%, F-99 improves the dough's wet gluten content, enhances dough strength, reduces damage caused by frozen storage and maintains the desired bread volume even after freezing for six months.

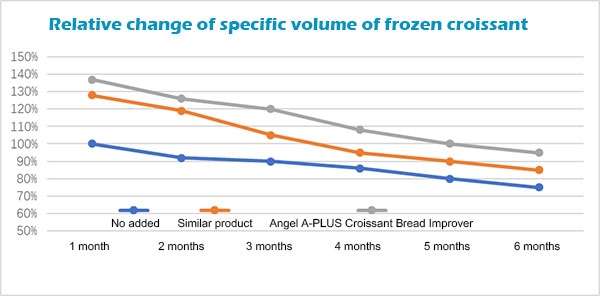

Angel Pastry Bread Improver A-plus is suitable for Danish-style pastries and all kinds of enriched doughs. It works by improving the stability of the gluten structure and reducing damage caused to doughs caused by ice crystals during freezing. The recommended dosage is between 2% and 3% mixed directly into the flour and other ingredients. It aids the reactivation of yeast within frozen dough and improve stretch, increase bread volume and crust and improve flake in pastries.

Meanwhile, Angel Freeze-Dried Yeast is capable of withstanding the low temperature damage of frozen dough, unlike regular yeast. It enters a dormant state under freezing conditions, suspending its fermentation activity, and resumes fermentation upon returning to room temperature. The excellent freeze resistance, stability and controllability of Angel Freeze-Dried Yeast make it a key component in producing high quality frozen dough products.

References

1. https://www.marketdataforecast.com/market-reports/frozen-dough-market.

2. Frozen bread dough: Effects of freezing storage and dough improvers.

3. Scouting the application of sourdough to frozen dough bread technology.