Scientist develops laser system to scan peeled potatoes for toxic compounds

Currently, only general quality tests are available for assessing potatoes with no accurate acrylamide detection. Food safety measures involve a person examining a sample and accepting an entire batch if the small selection passes.

Spectroscopic sensor

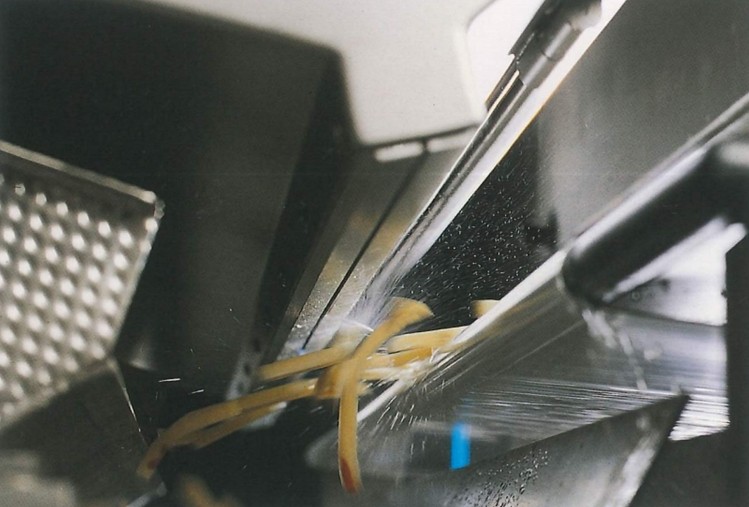

Dr Smeesters said the laser scanner will now be integrated into one of Tomra’s in-line sorting machines.

“When frying potatoes, acrylamide formation is one of the biggest concerns of the potato-processing agriculture industry,” she said.

“At present, raw potatoes that produce an excess of acrylamide cannot be detected in a fast, sensitive and non-destructive way.

“We worked with Tomra Sorting Solutions to develop a spatially-resolved spectroscopic sensor that identifies raw potatoes with high acrylamide precursor concentrations, on the basis of their internal scattering properties, in milliseconds.”

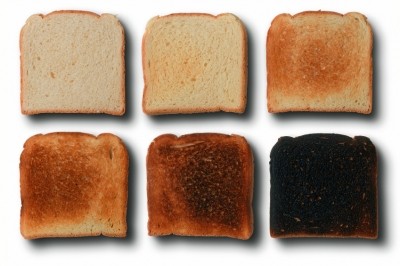

Earlier this year, the Food Standards Agency (FSA) issued warnings about eating over-fried potatoes, burnt toast and crisps that can contain cancer-causing chemicals such as acrylamide.

At present, raw potatoes that produce an excess of the carcinogenic chemical acrylamide cannot be detected in a fast, sensitive and non-destructive way.

“Not all potatoes result in excessive acrylamide formation during frying. We have sought to spot the undesirable potatoes when they are in their raw, peeled stage,” added Smeesters.

“After scanning with laser beams, the good potatoes will emit a different light signal than the unsuited ones leading to an unambiguous detection.”

Infrared light

The sensor works by scanning ‘free falling’ food items, such as potatoes, from both the front and back with a laser that employs ‘spatially resolved spectroscopy’, a non-invasive imaging technique using infrared light.

When the laser beam hits a potato, part of the light will be internally scatted during interaction with the tissue.

A bad potato produces a deviating internal scattering signal, owing to the high acrylamide precursors, and the system can recognize a 'fingerprint' of the undesirable food'.

The potato is then ‘knocked out’ of the batch blasted by a stream of air and into a reject bin before it hits the conveyor belt.

Photonics21 is the European Technology Platform (ETP) for photonics, a technology encompassing all of the products and processes around the emission, manipulation and detection of light.

It was set up in December 2005 to bring the community of photonics researchers and industries together.