Multivac opens HPP pack testing centre to tap growing industry interest

The Germany-based company said the site at its headquarters in Wolfertschwenden allows brand owners to assess different packaging concepts in relation to HPP technology and then to develop them further.

The centre has been developed as part of a strategy to tap into the growing take up of HPP technology as food companies seek to boost safety and shelf life of their products. HPP is used to reduce harmful bacteria in food and increase shelf life without the need to introduce heat or preservative.

HPP hub

“The test centre has been prepared for customers to think about HPP as a packaging solution rather than just a technology,” Multivac’s Dr Tobias Richter told FoodProductionDaily.com. “Our customers can bring their food products either packed or unpacked, since we obviously also pack the products here on site.”

It has a wide range of services, including technicians who run shelf life tests for a proposed packaging type. For this the firm works in partnership with experts from nearby independent institutes, added the HPP product manager.

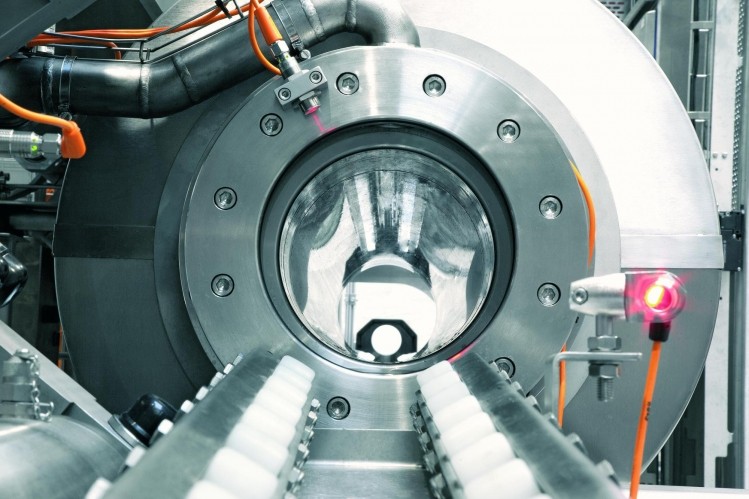

The testing hub also examines packaging design to maximising filling volume in HPP units with cylindrical autoclaves.

“We also look at packaging geometry with manufacturers,” said Dr Richter. “The majority of packaging designs have straight edges, whereas HPP vessels are cylindrical. This means there are challenges in fitting packaging into the cylinder to minimise the amount of dead space. We work to help companies adjust packaging and develop solutions to maximise filling volume and therefore efficiency.”

All adjustments in terms of converting, design and functionality can be made on site, he said.

“It’s a one-stop-shop that we believe can help improve efficiencies along the whole production line – saving companies both time and money.”

At present the centre has one HPP unit but the company said it would consider adding more if demand existed. The facility has four separate testing halls to maintain commercial confidentiality. All tests are carried out by Multivac although clients can attend if they wish, said Dr Richter.

The typical cost of a test programme ranges from between €1,000 and €9,000 depending on the length and complexity of the analyses carried out. However, the underlying aim of the facility was not to make money but to promote the technology, he added.

Vast potential

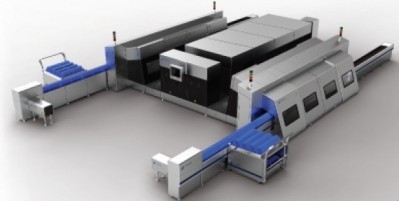

Multivac believes growth in industry take up of the technology will soar in coming years. At the beginning of 2011, the company unveiled what it said was a pioneering packaging system that integrated HPP technology into a fully automated packaging line is proof of this. The concept can be used to process both vacuum-packed and modified atmosphere packaging (MAP), it said.

“We see HPP as one of the fastest growing technologies,” said Dr Richter. “While Europe is still on the threshold of fully embracing the method, there is huge take up in North America and Asia – in places such as Japan and Australia.”

The different attitude of consumers in these regions compared to their European counterparts was a major driver in this, he added.

“Consumers in Europe are more conservative than in the US and Japan for example when it comes to accepting new technology,” said Dr Richter.