Interpack 2017

GEA sees ‘increasing interest in hygienic design and quick changeovers to meet “free-from” production needs’

The company made the comments during Interpack 2017 in Dusseldorf, Germany, (May 4-10) where it is presenting its processing and packaging machines to meet demand for more reliable, flexible, efficient, and imaginative packaging, under the theme "Packed with inspiration".

Variability of end-products

Andrew Wade, director, application marketing, Dairy and Food, GEA Group, said a key trend for the processing industry is maximization of efficiency for proper use of energy and a flexible production setup to cope with a high variability of end-products.

“Another trend is the “one-stop-shop” concept, to let the customer focus on all aspects of his final products,” he said.

“Thanks to the integration between Comas and Imaforni into GEA, the first “combined” orders for bakery lines have already been acquired and many projects are in the pipeline.”

According to Wade there is a growing interest in a fast and proactive after sales service with demand for remote assistance while machines are running.

GEA exhibited several machines for the bakery, confectionery, dairy and beverage sectors at the show including its GEA OxyCheck inline quality control system that measures the oxygen (O2) content in Modified Atmosphere Packaging (MAP).

Lollipop equipment

Other products were the GEA ConsiGma Blending System;entry-level GEA DeltaPak; Aquarius BunchWrapper and slicing and lollipop equipment.

“New developments include an entry-level thermoformer model and an ultra-hygienic vertical bagger system, as well as a coating and wrapping line designed to revive the lollipop market,” added Wade.

“One highlight at the fair will be a revolutionary non-destructive quality control system for modified-atmosphere packaging (MAP).

“The entry-level GEA DeltaPak is part of the recently re-defined GEA PowerPak range, which makes specifying a thermoformer for a particular application easier and more cost-effective by omitting functions that are not required.

“The line includes an OptiScan, a pre-scanning system to minimize give-away and increase the yield of sliced portions, a DualSlicer 1200 with Interleaver and Check 4000 weigher designed to slice raw ham, and a ShingleLoader to load portions automatically into the PowerPak packaging unit.

“This thermoformer is fitted with a new labeler, end-of-line lane convergers, and a non-destructive quality control system for MAP packaging. For vertical bagging users, there will be two continuous-operation SmartPackers, a CX250 with a multi-head weigher and a CX400.”

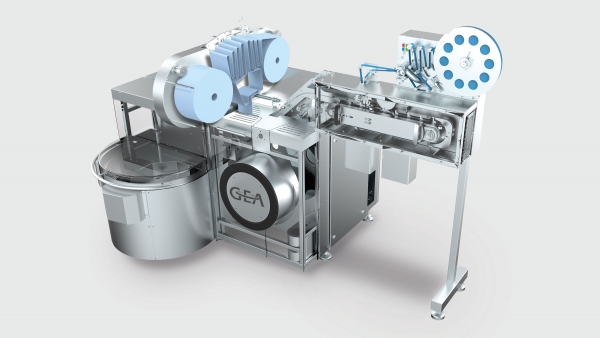

GEA recently launched its Aquarius BunchWrapper: the world’s first fully automatic line that forms, cools, coats, and wraps lollipops. GEA has now equipped the Aquarius BunchWrapper wrapping machine with labelers for inserting labels inside the wrapper film or directly on the stick.

This enables manufacturers to set off their products from their competition by adding information such as barcodes or promotional information such as logos and campaigns. Powder, syrup, or granule coatings provide additional taste, distinctive coloration, and special gloss.