Novel yeast to slash carcinogen acrylamide in fried potatos and baked goods, says Renaissance

The Canada-based supplier conducted in-house analysis with its non-GMO Acrylamide-Reducing (AR) baker’s yeast.

Matthew Dahabieh, CEO of the Renaissance Ingredients, told BakeryandSnacks:“To develop the AR baker’s yeast, we used adaptive evolution and selection methods—like those used in the dairy and agricultural industries—to speed up this capability of yeast,” Dahabieh said. “This allows our AR yeast to consume asparagine much faster than conventional yeast, and within the time frames required by modern food manufacturing processes.”

What is acrylamide?

Acrylamide, according to a recent report by UK’s Food Standards Agency (FSA), is a chemical produced naturally as a result of cooking starch-rich food at high temperatures.

“Biological effects of acrylamide exposure include cancer and damage to the nervous and reproductive systems,” the report says.

FSA’s report suggests that the amount of acrylamide that results from home cooking is far higher than most people suspect.

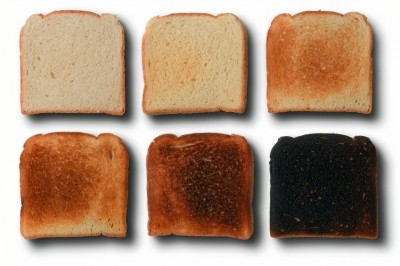

“The main point from the FSA report is that amount of acrylamide in fried potatoes and in toast rises quite high the darker you cook the food,” said a spokesperson on behalf of Renaissance Ingredients. He added that bread manufacturers, who previously thought they had a small acrylamide problem, now have a major problem due to toasting.

Testing process and results

To test the efficacy of the AR yeast in the lab, according to Dahabieh, blanched potatoes were incubated in either water alone, or a mixture of AR yeast and water at room temperature. Samples were taken at zero, five and 10 minutes, after which the samples were immediately dried with hot air. Then dried potato samples were cooked in corn oil in a batch fryer at 175 °C for five minutes. finally, the samples were cooled and analyzed for their acrylamide content.

The testing process showed a 70% reduction of acrylamide after 10 minutes and the company said they expect that by working with potatoes industry partners to refine the process in the future.

“We’ll be able to achieve reductions of up to 95%,” said Dahabieh.

Evaluation and application of AR yeast

The AR yeast functions like any other baker’s yeast “We don’t envision any significant nutritional changes from the AR yeast consuming asparagine in potato or other carbohydrate-rich food products,” said Dahabieh.

In the meantime, Renaissance Ingredients says it recognizes the potato industry does not traditionally use yeast in its manufacturing, except perhaps yeast extract as flavoring in certain recipes.

“Therefore, to successfully implement the AR yeast at a commercial scale, it will be necessary to adapt the AR yeast to industrial processes as a processing aid,” Dahabieh said. “From our perspective, a threshold number of such trials should create enough data and evidence for many companies to begin adopting our acrylamide-reducing baker’s yeast on a large scale.”